Every year at this time logistics managers have an annual meltdown if they move shipment out of areas affected by “Melon Season”. Here are seven lessons to help you cope learned in over 25 seasons from DSN Chemical Transportation.

What is Melon Season?

Melon Season is the time of year when produce is ripe and ready for shipment out of key growing areas like the Southeast United States (Georgia, Florida, Mississippi), Texas and Southern California. From Late May to Late June every year produce is ready for shipment to market. The growers are willing to pay just about anything to ship their produce to market as the alternative is for it to rot in the fields. Truckers know this and typically can make up for the rest of the year’s poor revenue in just a few short weeks if they play their cards right. For shippers this means lack of availability and skyrocketing rates.

How do you deal with melon season?

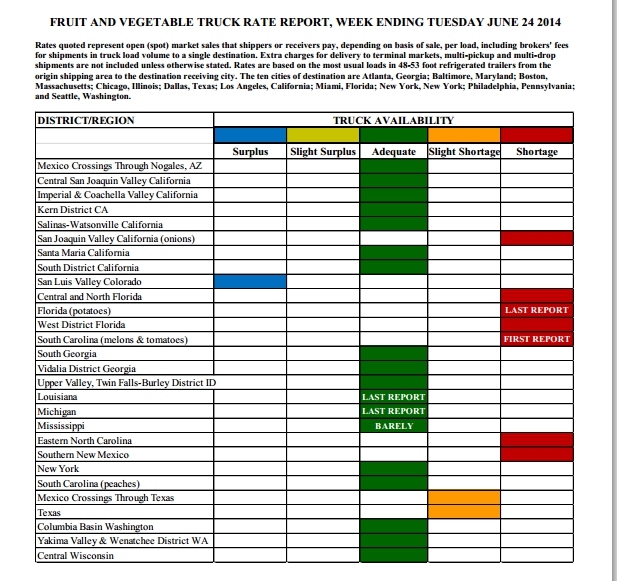

1. Check the Fruit and Vegetable Truck Rate Report

This is a report published by the US Department of Agriculture and can give you a “heads up” about what areas are experiencing capacity shortages. Us the report to help you plan.

http://www.ams.usda.gov/mnreports/fvwtrk.pdf

2. Book Early

This just makes sense. It happens every year. Try your best to plan out a few weeks in advance and book your orders with carrier in advance of melon season. You’re more likely to get a commitment and you won’t have to be looking for capacity at the last minute.

3. Have a core group of carriers that service the area

If you really want to minimize melon season headaches, then cultivate a core group of carriers all year round. Pay them fair rates all year (slightly above average) and you will have some leverage to pressure your carriers to get your loads covered before the carrier commits to produce, or other high paying loads this time of year.

4. If possible, stock up before melon season

It shouldn’t come as a surprise every year! If it’s possible, stock up in April. There is a cost/benefit analysis here of the increased cost of freight and service interruptions during melon season vs. the cost of carrying the extra inventory. If the numbers work, you should try it out.

5. Be on the phones during melon season

You never know when a load may get cancelled, not be ready, or a customer gets on credit hold. These situations happen for a carrier everyday and mean that they have a last minute truck available. If you’re not on the phones talking to carriers every day, all day, then you’ll miss these opportunities.

6. Consider alternate sources of supply during melon season

If possible, you may have a choice of vendors. If you can source an alternate either in an area that’s not affected, a local distributor, or off shore, you may have a better chance of maintaining supply at a reasonable cost during this difficult time of year.

7. BUDGET!

Truck rates during melon season can skyrocket to double and triple what they are during the low season. Be sure to plan this into your costing model If you budget a truck a month at $1500 freight per load, you may want to consider budgeting 2-3 loads at $3000, bringing up your annual average cost. You’re likely going to have to pay it anyway and having a negative freight variance on your reports is something no logistics manager wants!

Bonus tip

Give DSN Chemical Transportation a call. We’ve been moving freight out of affected areas for over 25 years. Let’s have a conversation about how we can help you minimize the impact of melon season next year.